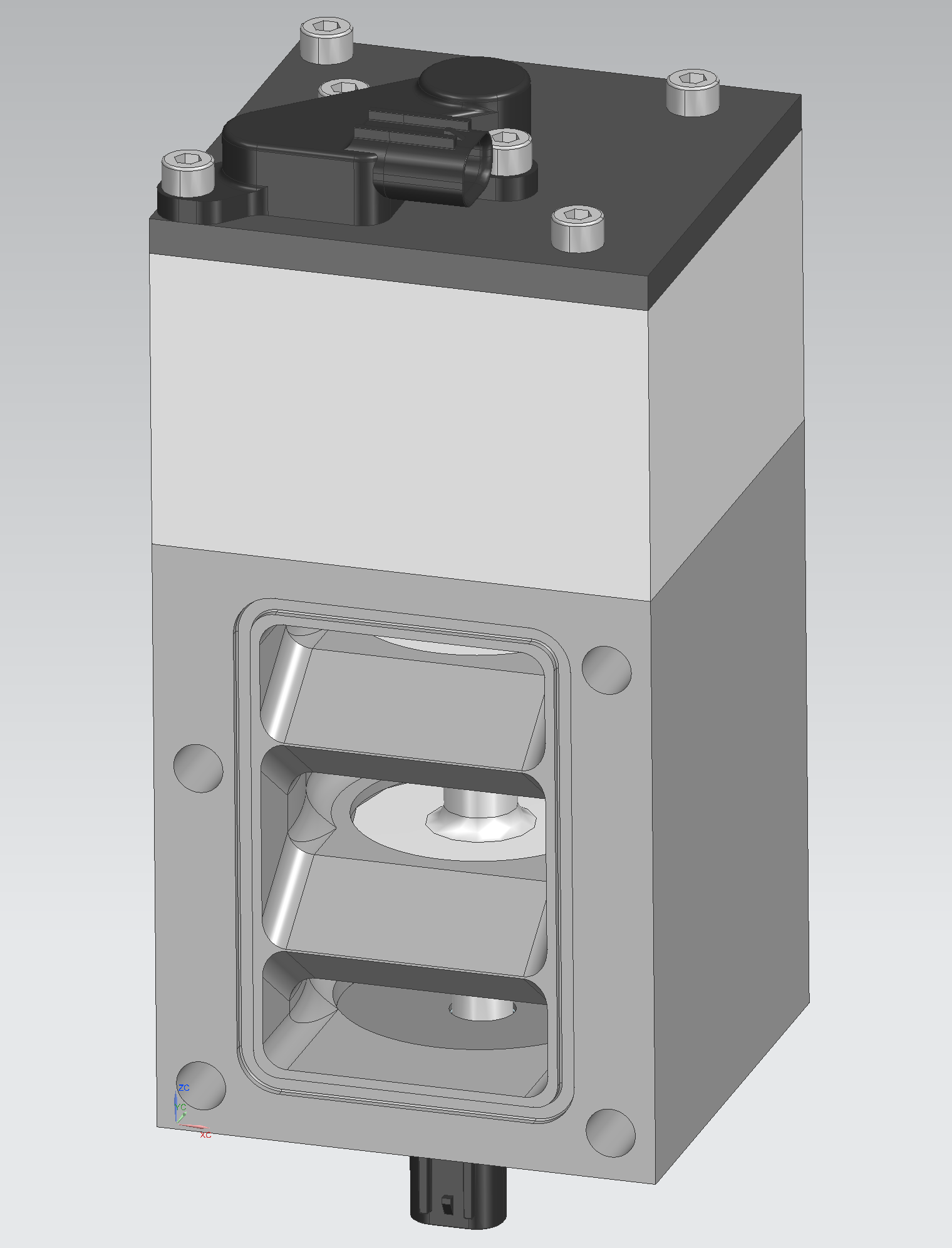

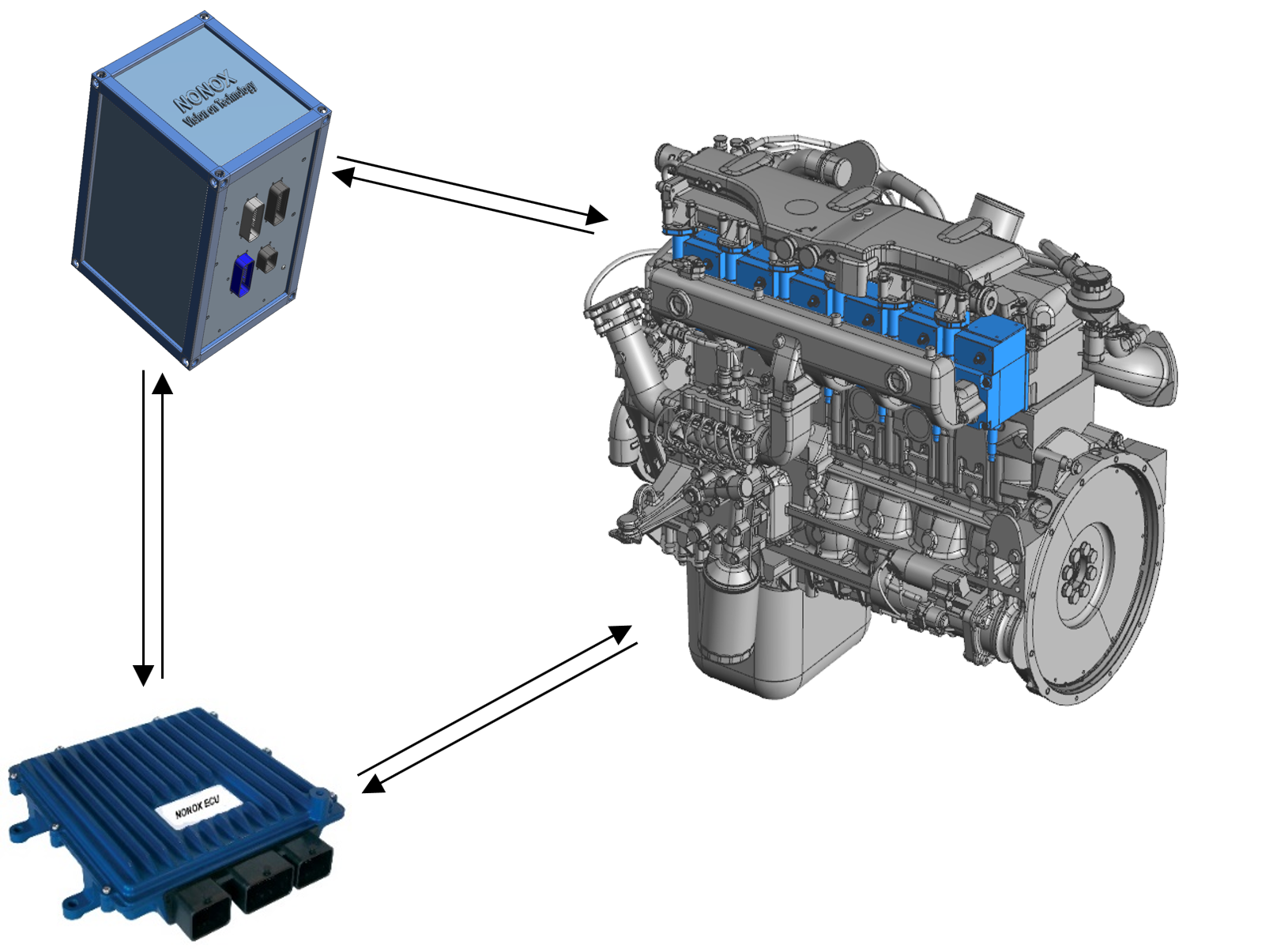

The mechatronic device Nonox developed results in a revolutionary improvement in engine efficiency of all Otto engines by eliminating throttle losses and reducing CO2 and NOx emissions. Nonox calls this device the Electronically Operated Control Valve (EOCV). The EOCV is a fast moving valve, which controls the amount of mixture for every cilinder cycle. This way it controls the load of the engine, and at the same time eliminates the throttle losses.

| Thermodynamic working principle | Component/product development | System integration |

|

Conventional throttle controlled engine

Nonox EOCV controlled engine

|

|

|

In the charge exchange loop of the above p-V diagram of the EOCV (bottom animation), it is clearly visible that the negative work done by the engine, is reduced significantly, relative to the conventional throttle engine.

Furthermore, the EOCV technology enables the implementation of Miller timing without further action. Also, by the cooling of internal mixture, the technology enables:

- Optimal ignition timing at full load

- A higher compression ratio

- Lower levels of raw NOx emissions

In the video below, you can see how easy the conversion to the Nonox system is: